Don’t let this happen to you.

Why pay attention to the diesel fuel in your generator storage tank? Because doing so might prevent a costly remediation and repair bill. A little attention to the fuel in the tank could have saved the owner of this generator nearly $13,000 in repairs.

Here’s what happened.

Recently our service team received a call to review a 180kW Caterpillar mobile generator that was idle for over three years and would not start.

Since fuel related issues are the cause of most engine fail-to-start situations, it didn’t take long for the technician to discover the problem. A quick fuel  sample revealed a tank full of dark, contaminated diesel fuel that likely caused the filters to clog. Replacing the filters did not get the engine to start.

sample revealed a tank full of dark, contaminated diesel fuel that likely caused the filters to clog. Replacing the filters did not get the engine to start.

Before any further diagnostics could happen, the aged fuel in the tank needed to go. P3 Generator Services recommended addressing this first. And since the generator was inactive for such a long time, we suggested having a Major Service performed on the generator to include a full inspection and oil and filter change after the tank cleaning is complete.

But what to do with a tank full of bad diesel fuel?

Tank cleaning is not an easy job. And for environmental reasons, it’s not a DIY project. Fuel disposal needs to be done by a professional service with the right equipment and permits.

With customer approval to handle the project, we called Adler Tank Rentals of South Plainfield, New Jersey – a national fuel tank services provider with extensive experience in the removal of contaminated fuel in storage tanks.

The process included:

- Removing all the old fuel from the tank and collecting it into 55-gallon steel drums

- Water-jetting the tank to dislodge the built-up sediment on the tank walls and floor

- Removal of any remaining sludge and water and placed in separate 55-gallon drums

- Finally, vacuum-dry the tank interior to remove any remaining water and debris

With the tank now clean and filled with fresh new fuel, a P3 technician set out to run and inspect the generator. But even with quality, viable diesel fuel in the tank and fresh fuel filters installed, the engine still would not start.

What’s the problem?

Old fuel becomes thick and laden with sediment from the tank. Fuel filters become clogged as they trap this debris in an attempt to prevent it from going any further up the fuel delivery system.

Like trying to suck an extra-thick chocolate shake through a tiny straw, the fuel pump on the generator engine needs to work very hard to get the fuel to flow. The strain was too much, and the pump failed. Likely during the repeated attempts to start the engine before calling P3. Additionally, some sediment from the tank found its way through the lines and clogged the fuel injectors as well.

Significant repairs were necessary to get this generator back online.

A breakdown of the repairs performed and the expenses incurred:

- Remove fuel and clean tank = $3500

- Disposal of collected fuel and sludge = $900

- Repair costs to replace the fuel pump, injectors, gaskets, fuel solenoids, and just about every other fuel delivery component = $8500

- The total cost to get this generator operational after three years of sitting unused = $12,900.

Three elements caused this issue to become such a considerable expense:

- Failure to run the engine (exercise) regularly – It is necessary to routinely run a generator, at least long enough to bring the engine up to operating temperature – preferably under load, if possible. We suggest weekly operations.

- Lack of regular service – Over time, belts, hoses, and other components of a generator can deteriorate and fail. Regularly scheduled inspections by a trained generator professional will detect potential issues before they become significant problems.

- Not maintaining the fuel – Fuel is one of the most neglected components of engine-driven equipment. But by its very nature, it is arguably the most important. As you see in this example, the problems cascaded across many expensive areas of repair. Had the fuel been adequately maintained with frequent testing, stabilizing, and protecting against the growth of bacteria, this generator may not have needed such an expensive repair.

Don’t let this happen to your generator.

You bought it to protect you and your family, your business, or your home against power outages. Protect the fuel, maintain the engine, and stick to a regular schedule for exercising. Because when weather strikes, there is little time to lose.

A Fuel Management Comparison

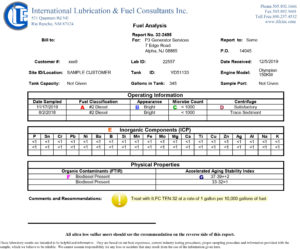

An annual Fuel Management plan from P3 Generator Services for this 180kW generator with a 300-gallon fuel tank is $365 – costs vary depending on the size of the fuel tank frequency of testing. Plans include fuel sampling, testing, and treating the fuel with a stabilization formula. Customers receive complete fuel condition reports with each test performed.

Over time, these reports provide actionable insight into any developing changes to fuel quality. In this way, future treatments can be adjusted accordingly in a proactive vs. reactive approach to protecting your fuel and, consequently, your generator.

As the example shown here proves, $365 per year in fuel maintenance is a lot easier to budget than an unexpected $12,900 repair bill.

Protect yourself from costly repair bills. Subscribe to our Fuel Management Plan Today.

To Learn More:

Read our Report: WHAT YOU CAN’T SEE MIGHT BE KILLING YOUR GENERATOR.

What’s important to understand is that over time fuel loses its ability to function properly. It becomes unstable as it ages and molecular particulates fall out of the fuel at an increasing rate. And this is how it’s bad for your generator. Click the link above to read more.

But what about the drums of old fuel and sludge? These drums were now an environmental hazard, and proper disposal was critical. For this, we turned to ACV Enviro of Elizabeth, New Jersey. They maintain the required certifications and permits to provide safe and compliant waste fluid, collection, storage, and disposal.