Generator Routine Maintenance and Operational Testing:

An overview of what’s inside Chapter 8 of the NFPA 110 Standard

Do you own, operate, or manage a facility where human lives depend on uninterrupted electrical power, like; nursing homes and hospitals?

If so, your priority should be to make NFPA 110 your guide to understanding these legally enforceable generator care provisions.

What are generator maintenance best practices? Without clear guidelines, this is open to interpretation. NFPA 110 provides the means to understand proper generator maintenance and testing uniformly.

To help you become better informed, we offer an easy-to-read explanation of the three main points; testing and maintenance, load banking, and fuel condition management.

Testing & Maintenance

All aspects of the generator require periodic testing to ensure proper operation at its rated specifications. In other words, will it provide the necessary electrical power for its intended use?

NFPA 110 guidelines establish when and for how long routine testing should occur.

It includes more than whether or not the generator will start. It covers all the related components and the methods necessary for testing, such as; automatic transfer switches and batteries.

Testing must be performed routinely and after any repair or maintenance service to the generator. Maintaining a schedule and keeping accurate records of all maintenance and testing is also outlined in the NFPA 110.

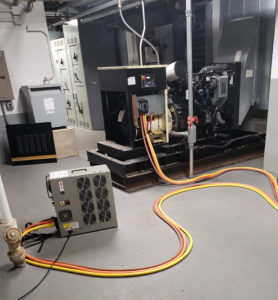

Load Banking

Are you a Level 1 Facility? If so, and your diesel-powered generator doesn’t reach 30% of its rated kW during monthly tests, NFPA 110 requires a Load Bank to ensure it can attain its data plate rating during an actual emergency.

What is a load bank? You can learn more about load banking here.

Fuel Maintenance (Diesel)

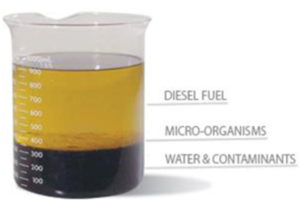

Yearly fuel quality testing is mentioned in section 8.3.7 of the current NFPA 110 Standard. But the reference is vague to using appropriate ASTM D975 specifications or the generator manufacturer’s recommendations. However, ASTM standards are designed to be the reference point for newly refined fuels. They have less significance after the fuel has gone through several distribution levels and stored for more extended periods.

Fuel is a vital part of the success of your emergency power system. Over 95% of emergency call-outs are traced back to poor fuel quality. While fuel is often out of sight and out of mind, it’s important to note that quality is adversely affected by many factors. Routine sampling, testing, and reporting are critical to avoiding future generator start/run problems.

There is much debate on whether ASTM D975 testing should be the only variable for determining fuel quality in standby generator systems. Expect more from NFPA 110 in the future on this topic.

Programs are available that provide fuel sampling and testing services beyond basic ATSM D975 standards to address the effects of long-term storage in fuel. To learn more about this, click here.

P3 Generator Services offers many services to help ensure your generator is not just NFPA 110 compliant, but more importantly, to ensure your generator is in the best condition to protect you and the ones in your care.

FACT SHEET: ITM of Emergency Power Systems (An NFPA Publication)

P3 Generator Services

7 Edge Road, Alpha, New Jersey 08865

908-454-1124